Wondering Where to Start Your Maintenance Transformation?

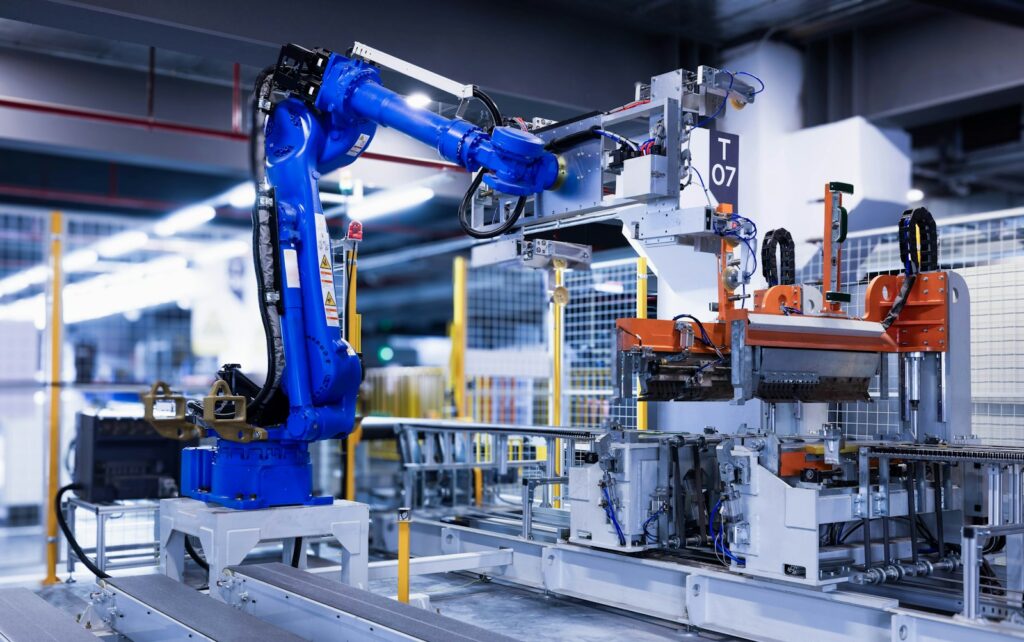

Production Line Critical Equipment Analysis

Identify which equipment failures would halt production and prioritize maintenance strategies for maximum production protection.

Manufacturing Schedule Integration

Develop maintenance windows that align with production schedules, planned shutdowns, and changeover periods to minimize production impact.

Manufacturing Compliance & Safety Assessment

Evaluate current maintenance practices against manufacturing regulations (FDA, ISO 9001, OSHA) and develop compliant maintenance procedures.

Production Cost Impact Analysis

Calculate the true cost of production downtime and project savings from optimized maintenance strategies and improved equipment reliability.

Our proven manufacturing-focused methodology ensures CMMS implementation that supports production goals and delivers measurable manufacturing results.

We were hemorrhaging money on emergency repairs. Maintenir’s predictive approach cut our reactive maintenance by 60% in the first year. Our equipment has never run better.

Coordinating maintenance across 8 facilities was a nightmare. Now we have standardized processes, real-time visibility, and consistent performance everywhere. Game-changer.

OR